Broadband Foam Absorbers

ABS-SLF

ABS-SLF is a range of flat sheet, lightweight carbon loaded foam absorbers. The flat sheet absorber is a multilayer structure which consists of individually tuned absorbing layers each with their specific dielectric gradient to obtain its best possible matching with the impedance of air. The absorber sheets have a controlled dielectric loading which is impregnated with a binder system and fire retardant additives. This absorber material is available in 6 different thicknesses where each type is related to its operating frequency. Typical reflectivity level of the absorber is -17dB at normal incident energy.

ABS-SLF is a typical broadband absorber which find its use in free space and cavity applications. For specific applications where the absorber is used in a harsh environment we can supply the absorber material equipped with protection like, vinyl, tissue or coating.

Applications

- Electronic cabinets

- Antenna radomes

- Anechoic structures

- Reduction of cross talk between antenna systems

Datasheet ABS-SLF ![]()

ABS-ASF

ABS-ASF is a range of flat sheet flexible microwave absorbers produced from a polyurethane foam material by impregnation with a dielectric carbon loading. Different dielectric grades and thicknesses are available, the material is typically characterized by its level of insertion loss at a given frequency. By adjusting its thickness and losses one can tune insertion loss properties to optimize the required attenuation. Lossy foam sheet absorbers are a low cost solution for absorber unwanted RF signals above 1 GHz.The absorber is a carbon foam based material if needed the material can have an additional treatment by impregnation of a coating to avoid dust release.

Furthermore if needed we can supply the absorber material equipped with protection like, vinyl, tissue or coating. The absorber material can also be used for the isolation of antennas by insertion loss properties. ABS-ASF is often supplied with a self-adhesive backing, the material easily be cut with a knife.

Applications

- RF-radio’s, amplifiers, oscillator cavities

- TV satellite systems

- Attenuate surface currents

- Resolve RF leakage areas

Datasheet ABS-ASF ![]()

ABS-LCF

ABS-LCF is a range of light weight open cell (reticulated) foam microwave absorbers. The single layer reticulated polyurethane foam material is coated with a dielectric carbon solution with fire retardant properties. Due to its open cell structure and a specific production process the absorber material obtains a dielectric conductive gradient to meet a excellent RF performance level. To meet customers mechanical and RF requirements different thicknesses are produced, typical thicknesses are 5, 10, 15 and 25mm. Typical frequency of operation is above 3 GHz, the thickest material is used in the low frequency range.

When a reflectivity performance is required the material can be supplied with a integrated metal backing. Similar as with our other polyurethane based absorber also ABS-LCF can be supplied equipped with a protective tissue, typical a vinyl fabric is used.

Applications

- Around antenna feeds to reduce surface currents

- In antenna shrouds to reduce side lobes

- Radar absorbing blankets (often covered with vinyl fabric for harsh environment)

- Inside RF-cabinets to suppress standing waves

- Cross talk reduction between RF-systems

Datasheet ABS-LCF ![]()

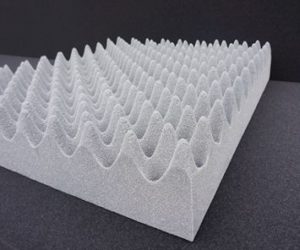

ABS-CSF

ABS-CSF is a range of high performance electrically taper shaped microwave absorber. The absorber is made from a light weight polyurethane foam material which is impregnated with a dielectric carbon and fire retardant solution. ABS-CSF has its typical convoluted front face shape the material provides an ideal impedance taper which gives the absorber a superior RF performance at higher frequencies. Due to its specific shape the absorber material remains at his high performance level independent the angle of incident energy or the signal polarization.

Three different height are produced : 3, 4 and 6 inch height. Typical frequency of operation is above 1 GHz.

Applications

- Anechoic enclosures

- RF test boxes

- Indoor metal structures

- Antenna positioning systems

Datasheet ABS-CSF ![]()

ABS-ESF

ABS-ESF is a range of high performance electrically taper shaped microwave absorber. This absorber has a similar convoluted shape as ABS-CSF, the base material used to produce ABS-ESF is an open cell (reticulated) polyurethane foam. The difference and advantage of ABS-ESF versus ABS-CSF finds its way when used in high humidity and high power applications. The absorber is made from a light weight polyurethane foam material which is impregnated with a dielectric carbon and fire retardant solution.

ABS-ESF has its typical convoluted front face shape the material provides an ideal impedance taper which gives the absorber a superior RF performance at higher frequencies. Due to its specific shape the absorber material remains at his high performance level independent the angle of incident energy or the signal polarization. Three different height are produced : 3, 4 and 6 inch height. Typical frequency of operation is above 1 GHz.

Applications

- Anechoic enclosures

- RF test boxes

- Semi outdoor applications

- Outdoor test sites with temporary use of absorbers

Datasheet ABS-ESF ![]()